Manual Powder Coating Equipment has long been a staple for those seeking precise and hands-on powder coating results. As a dedicated DIY enthusiast exclaimed, "The

Manual Powder Coating Equipment I own gives me the control I need to create unique finishes on my projects, and it's surprisingly easy to use." Another small business owner shared, "Our manual powder coating equipment has been a reliable workhorse, allowing us to handle small-scale jobs with great quality and cost-effectiveness."

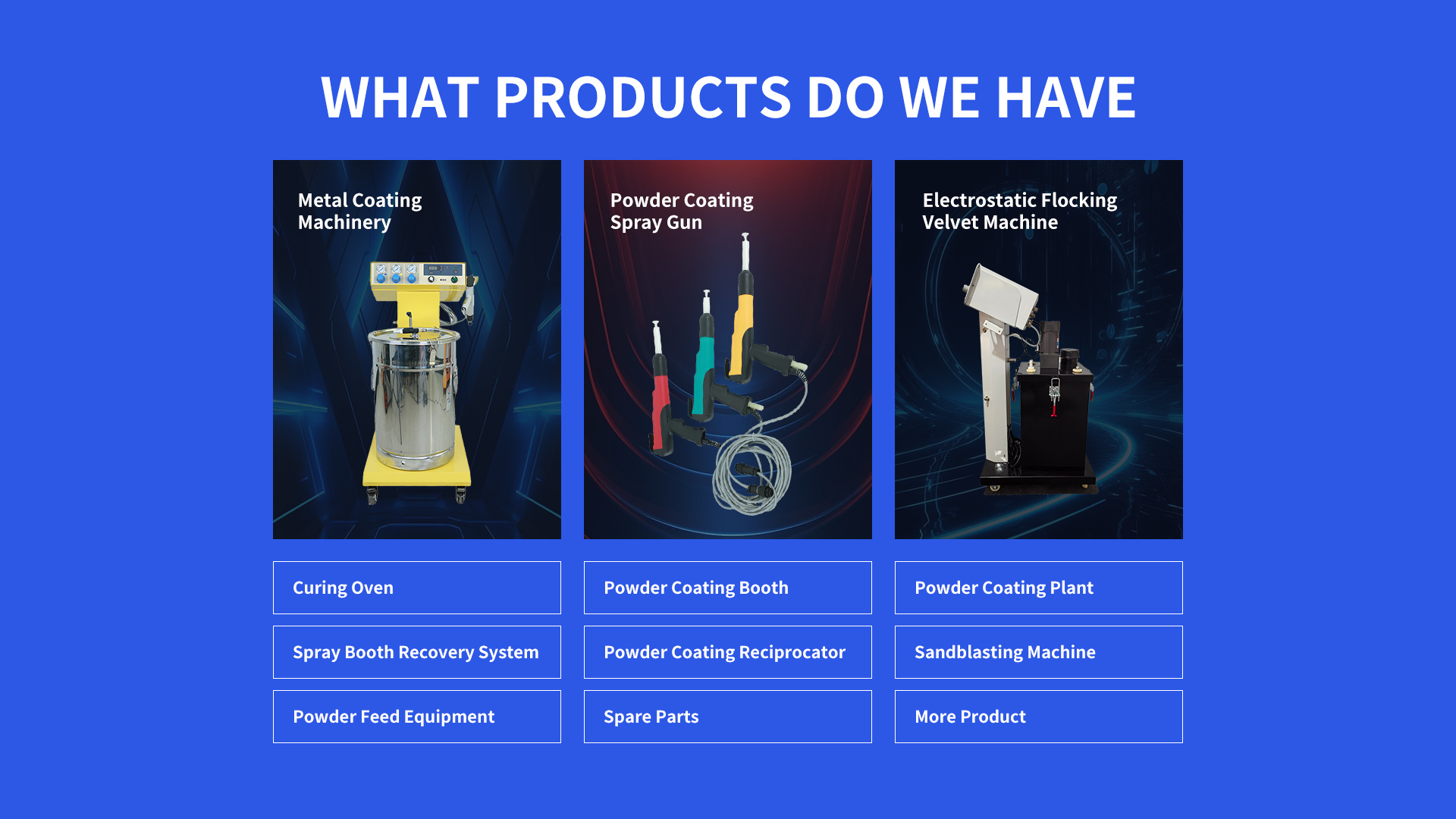

Manual Powder Coating Equipment typically includes a powder coating gun, a powder feeder, and sometimes basic accessories. The powder coating gun features a handle for comfortable grip, a powder flow control valve that allows operators to manually adjust the amount of powder released, and a nozzle for spraying the powder. The powder feeder is usually a simple container with a mechanism to feed the powder to the gun. In some models, there may be a basic electrostatic charging feature integrated into the gun to help the powder adhere better to the workpiece.

This type of equipment is ideal for small-scale projects. DIY hobbyists often use it to coat items like metal crafts, small furniture parts, and automotive accessories at home. Small workshops that deal with custom orders or limited production runs can also benefit from manual powder coating equipment. It is suitable for coating delicate or intricate items where precise control is required, as the operator can adjust the powder flow and spraying pattern manually.

The price of

Manual Powder Coating Equipment varies depending on its features and quality. Basic sets, which include a simple powder gun and a basic powder feeder, can range from $200 to $600. These are suitable for occasional DIY use. Mid-range equipment, with better quality components and perhaps a basic electrostatic function, can cost between $600 and $1500. High-end manual powder coating equipment, featuring advanced powder flow control and more reliable electrostatic charging, can exceed $1500.

Before using the equipment, ensure that the powder feeder is filled with the appropriate powder and that all connections are secure. Adjust the powder flow control valve to the desired setting based on the size and nature of the workpiece. Hold the powder coating gun at a consistent distance (around 15-20 cm) from the workpiece and move it in a smooth, even motion while spraying. After use, clean the powder gun and feeder thoroughly to prevent powder buildup.

Consider your project scale. If you only have small-scale or occasional projects, a basic manual powder coating equipment set will suffice. For more frequent use or projects that require higher precision, look for equipment with better powder flow control and, if possible, an electrostatic feature. Also, check the build quality of the equipment and read reviews from other users to ensure its reliability.

Wear a dust mask, safety goggles, and gloves to protect against powder inhalation and potential splashes. Ensure that the work area is well-ventilated to avoid the accumulation of powder particles. Keep the equipment away from flammable materials, as powder can be combustible.

The design of

Manual Powder Coating Equipment is rational for its intended use. The manual control over powder flow allows for precise application, especially for detailed work. The relatively simple structure makes it easy to operate and maintain, reducing the need for complex technical knowledge. For small-scale projects, it offers a cost-effective solution compared to automated equipment.

Q: What if the powder doesn't flow evenly from the

Manual Powder Coating Equipment?

A: Check the powder flow control valve to make sure it is not blocked or stuck. Also, ensure that the powder in the feeder is not compacted. Adjust the valve as needed to achieve an even flow.

Q: Can I use different powder types with my

Manual Powder Coating Equipment?

A: Yes, but it is important to clean the equipment thoroughly between different powder types to avoid contamination, which could affect the coating quality.

Q: How often should I clean my Manual Powder Coating Equipment?

A: Clean the equipment after each use to prevent powder buildup, which can affect its performance. For a more thorough cleaning, disassemble the powder gun and feeder periodically and clean each component.

Q: What if the electrostatic feature of my Manual Powder Coating Equipment isn't working?

A: Check the connections and ensure that the power source (if applicable) is working. If the problem persists, consult the manufacturer's troubleshooting guide or contact their customer service.

Q: Can I upgrade the features of my Manual Powder Coating Equipment?

A: In some cases, it may be possible to upgrade certain features, such as adding a more advanced electrostatic charging system. However, this depends on the design and compatibility of the equipment. It is best to consult the manufacturer for advice.

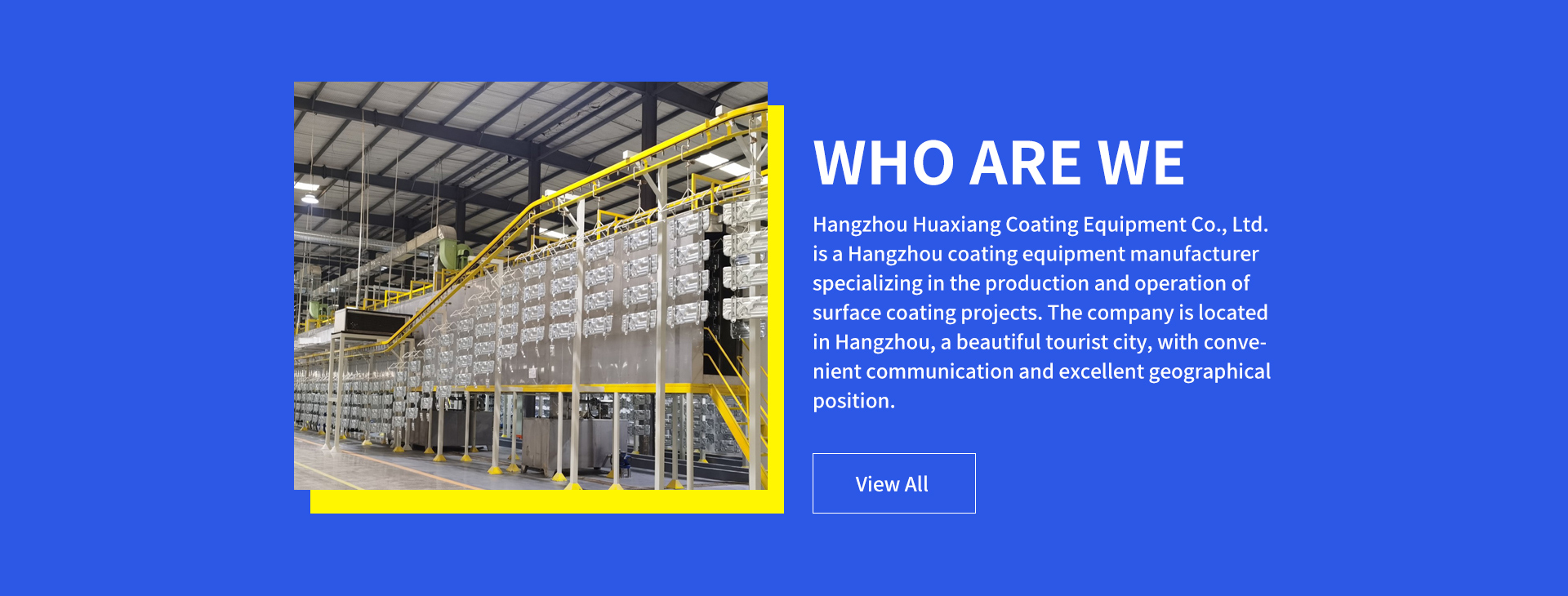

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com